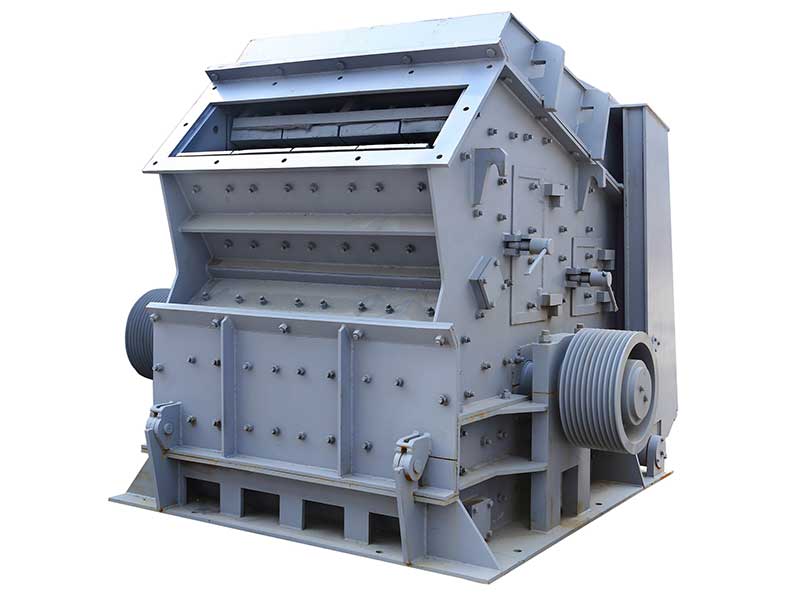

Hammer Crushers

Product Specification:

Φ 2.5×40 - Φ 6.0×95

Production Capacity:

180 - 1000 (T / d)

Product Description

Feature

Working principle

Specification

Hammer crushers are used to crush various medium hard and weakly abrasive materials. The compressive strength of the material does not exceed 100MPa, and the moisture content is less than 15%. The crushed materials include coal, salt, chalk, gypsum, bricks and tiles, limestone, etc. It is also used for crushing broken wood, paper, or waste of asbestos cement with strong elasticity and toughness, as well as for recycling asbestos fibers.

Wheeled cement kiln (cement kiln) for preparing dry and wet clinker.

Rotary Kiln (Mining Chemistry): Magnetization and Oxidation of Roasted Iron Ore in Steel Plants

Wheel kilns use high-strength aluminum ore for roasting in plant smelting.

Rotary kilns used in aluminum alloy barbecue factories, chrome plated barbecue factories in chemical factories, and powder factories.

Rotary kilns (lime kilns) are used for active calcification of lime and dolomite in steel and ferroalloy plants.

Crusher motor driven crushing high-speed rotating rotor cavity. From the upper nozzle material feedback to the machine, the impact of hammer impact shear grinding and high grinding speed. In the lower part of the rotor equipped with the sieve plate, the grain size of the grinding material is smaller, and the size of the sieve leakage through the screen is larger than that of the coarse particle size. The resistance of the sieve leakage is larger than that of the coarse particle size. It is left in the sieve plate to continue the hammer impact grinding, and finally discharged out of the machine through the sieve plate.

| >Specifications | >Feeding Size (mm) | >Discharging size (mm) | >Capacity (m³/h) | >Motor power (kw) | >Total weight (t) | >Dimensions(L×W×H) (mm) |

| >PCΦ400×300 | >≤200 | >≤25 | >5-10 | >11 | >0.8 | >900×670×860 |

| >PCΦ600×400 | >≤250 | >≤30 | >10-22 | >22 | >2.26 | >1200×1050×1200 |

| >PCΦ800×600 | >≤250 | >≤35 | >18-40 | >55 | >4.8 | >1310×1180×1310 |

| >PCΦ1000×800 | >≤350 | >≤35 | >25-50 | >75 | >5.9 | >1600×1390×1575 |

| >PCΦ1000×1000 | >≤350 | >≤35 | >30-55 | >90 | >8 | >1800×1590×1775 |

| >PCΦ1250×1250 | >≤350 | >≤35 | >35-65 | >132 | >14 | >2060×1600×1890 |

| >PCΦ1400×1400 | >≤350 | >≤35 | >50-100 | >280 | >32 | >2365×1870×2220 |

| >PCΦ1600×1600 | >≤350 | >≤35 | >100-150 | >480 | >37.5 | >3050×2850×2800 |

قماCement kilns are mainly used for clinker calcification, which can be divided into dry cement kilns and wet cement kilns. The metal chemical furnace is mainly used for the roasting and magnetization of light iron ore in the metallurgical industry and steel plants, the roasting of oxidized olive sauce, grapes, and magnesium, and the roasting and roasting of high-quality alumina ore in smelters Aluminum manufacturing plants use clinker and aluminum hydroxide, while chemical plants use clinker and aluminum hydroxide to bake chromium. Lime kilns are mainly used for baking live lime, while dolomite lamps are used in steel and ferroalloy plants.

More products you want to know!